DRY ICE BLASTING

AN INDUSTRIAL CLEANING SYSTEM THAT COMBINES

MAXIMUM EFFICIENCY WITH LOWEST

ENVIRONMENTAL IMPACT

BENEFITS OF DRY ICE BLASTING

CRYOGENIC BLASTING can enhance your business efficiency and increase your PRODUCT ’s VALUE

REDUCE DOWNTIME

Quicker than other cleaning methods. It doesn’t require dry or cool downtimes.

IMPROVE YOUR PRODUCT’S QUALITY

Working with cleaner machinery results in BETTER PRODUCTS, but also in higher production quality with plant efficiency and less waste.

INCREASE EFFICIENCY

There is NO need for disassembly. You clean without interrupting your production line.

ENVIRONMENTALLY FRIENDLY

DRY ICE is obtained from reclaimed CARBON DIOXIDE. Eliminates need for chemicals during the cleaning process.

NO SECONDARY WASTE

DRY ICE BLASTING reduces the amount of secondary waste for disposal.

NON-ABRASIVE

This cleaning method does NOT harm the substrates.

NON-TOXIC AND NON-CONDUCTIVE

CO2 is NON toxic and, more importantly, NON-conductive. Therefore it can be used to clean online and with the flow directed on electrical systems.

LESS INTERVENTION TIME

Fewer operators and less intervention and handling time.

OPERATOR SAFE

The work environment is safer due to the reduction of disassembly operations and use of chemicals and to the increasing of the visibility of controls and safety signs.

How does it work?

Dry ice

Dry ice is solid state CO2 (Carbon Dioxide) at a temperature of 78.5 C.

Carbon dioxide is an odorless and non-toxic gas.

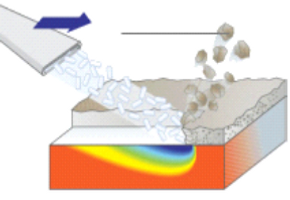

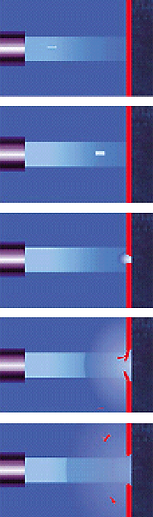

The principle of dry ice blasting

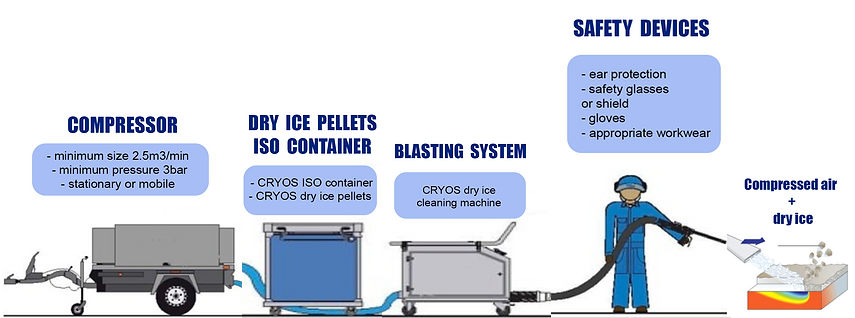

Dry ice pellets are directed from the machine’s hopper into a metering device and then extruded by compressed air.

The particular structure of the nozzle of the gun extrudes pellets up to 300m/sec, projecting them to the surface to be cleaned.

By mechanical effect, pellets penetrate the dirt layer and, by thermal effect, sublimate expanding its volume up to 500 times. This results in the detachment of the layer from the support without any abrasion.

During this process, solid dry ice pellets are transformed into gas without leaving any trace except for the removed residue.

No other cleaning or abrasive substances are used together with dry ice.

What do you need to clean with dry ice?

Within the broad range of industries of dry ice blasting

application, you will find yours too.

Automotive

Foundry

Food and beverage

Printing

Industrial machinery

Paper / Newspaper industry

Large motors

Chemical industry

Pipe-line

Production line

Before and after dry ice blasting

IMPROVE YOUR COMPANY’S QUALITY AND YOU WILL IMPROVE THE WORLD

TRANSFORM THE CONCEPT OF CLEANING: FROM AN EXPENSIVE NECESSITY TO AN EASY AND FAST METHOD TO:

- INCREASE YOUR PRODUCTION’S VALUE

- INCREASE YOUR PRODUCT’S VALUE

- PROTECT THE ENVIRONMENT

- PROTECT PEOPLE

Interested, but looking for more certainties and answers?

Contact us to learn more about the benefits of DRY ICE BLASTING for your specific needs.

PIEMONTE HEADQUARTERS

Via Alta Furia 51

Peveragno (CN)

Tel 0171 34 81 32

digitale@cryos.it

FRIULI BRANCH

Viale Grado 57/4

Pavia di Udine (UD)

Tel +39 327 4637852

rinomontina@gmail.com

UMBRIA BRANCH

Via dei Fiordalisi 19

Magione (PG)

Tel +39 333 3246460

filiale5@cryos.it

LOMBARDIA BRANCH

Via Vittorio Veneto 23

Pianengo (CR)

Tel +39 380 8923367

filiale2@cryos.it

VENETO BRANCH

Via Sesta Strada 29/A

Bagnoli di Sopra (PD)

Tel +39 049 0990259

filiale3@cryos.it